Innovations

Intelligent solutions for more

comfort and safety

Pacoma is one of the world's leading suppliers of hydraulic cylinders. Our cylinders are extensively used in the construction machinery industry, the automobile industry, and in engineering applications as well as in logistics and material handling. Furthermore our cylinders can also be used in agricultural and maritime applications etc.

Pacoma stands out with its individual designs, its consistently superior global quality and its high-capacity production facilities. Our factory in Eschwege, Germany, can singularly handle a quarter million units per year working at normal capacity. With the opening of a dynamic modern facility in China in 2011, Pacoma is even better positioned to serve its customers with high output and convenient logistics.

Our success is the product of decades of experience. Over the course of more than 40 years, we have developed, designed and produced hydraulic cylinders of nearly every possible type. Our aim of developing and maintaining long-term relationships with our customers means that you can rely on our comprehensive technical expertise and top quality innovative products. We operate to serve our customers bearing in mind always our slogan:

„New thinking with tradition”.

Decades of experience, modern facilities equipped with state-of-the-art technology and the unceasing efforts for continual improvement by our well-trained employees – these are the cornerstones for our innovative range of products.

To maintain this competitive edge, Pacoma is continually investing in research and development, in acquisition of technical knowledge, and in the ongoing education and qualification of its employees. Likewise Pacoma is consistently investing in new production technology – be it in the form of new machinery, robotic assembly or supporting software.

It is our dedicated employees, however, who are – and remain – the crucial element in Pacoma’s success as they bring their know-how and technical expertise to serve our customers. Their skill and dedication are keys to our effective and robust custom-made hydraulic cylinders.

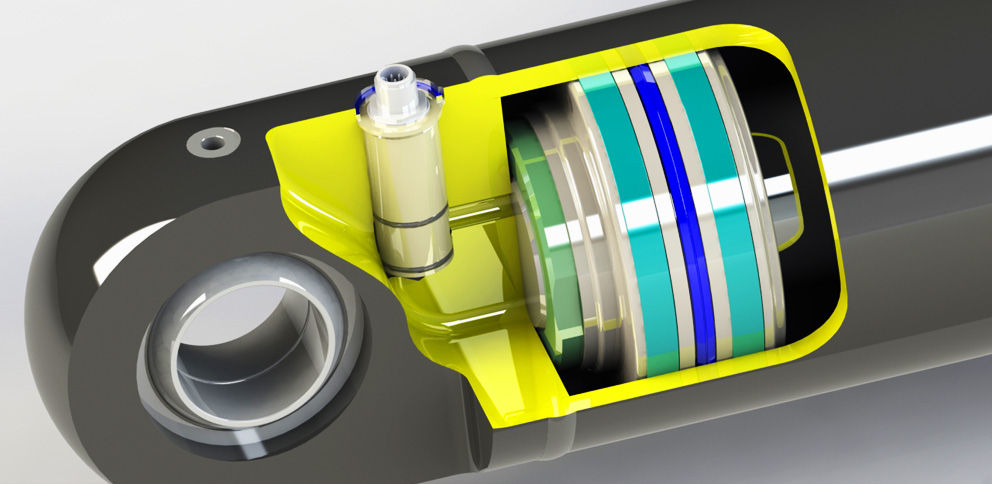

The new Pacoma IRM Sensor is now available, the culmination of years of research and development work. With the new solution, a team of engineers and developers has succeeded in integrating radar technology in a highly robust cylinder sensor to deliver exceedingly precise measurement results.

The patented sensors enable precise measurement and exacting control of hydraulic cylinders. And, of course, they function with absolute reliability regardless of vibrations and shocks. Should it be necessary to make a sensor exchange, this can be done at the construction site in less than two minutes and without any contact with hydraulic fluid – a huge advantage compared to the four hours typically required to exchange existing in-cylinder technologies. On top of this, the new sensor is surprisingly economical – a winner on every front.

Since the new IRM Sensors can deliver measurement results in multiple media (not only in hydraulic fluid and oil, but also in air), a whole new range of applications is available. Pacoma is open to the use of its IRM Sensors in other products and industries and will be pleased to respond to any inquiries.

The abbreviation PaCE stands for Pacoma Cylinder for Excavators – a special type of hydraulic cylinder. These cylinders (as the name indicates) are used particularly in excavators – from the smallest model up to 50-ton material-handling machines.

Excavators typically work under extreme conditions, and for just that reason their cylinders must also fulfill stringent requirements. To make this possible, Pacoma makes use of innovative features such as LiRe, PaStab, CuSt and P3S.

LiRe is our patented piston-locking system that significantly increases durability and simplifies cylinder maintenance. PaStab refers to a valve system that ensures secure positioning of a mobile hydraulic machine even on uneven ground. CuSt is our sophisticated cushioning system. Even at maximum speed and loads it protects the cylinder as well as the steel structure of the machine against load peaks in the final position. Last but not least, our piston stroke and speed sensor system P3S makes it possible to automate defined machine movements.

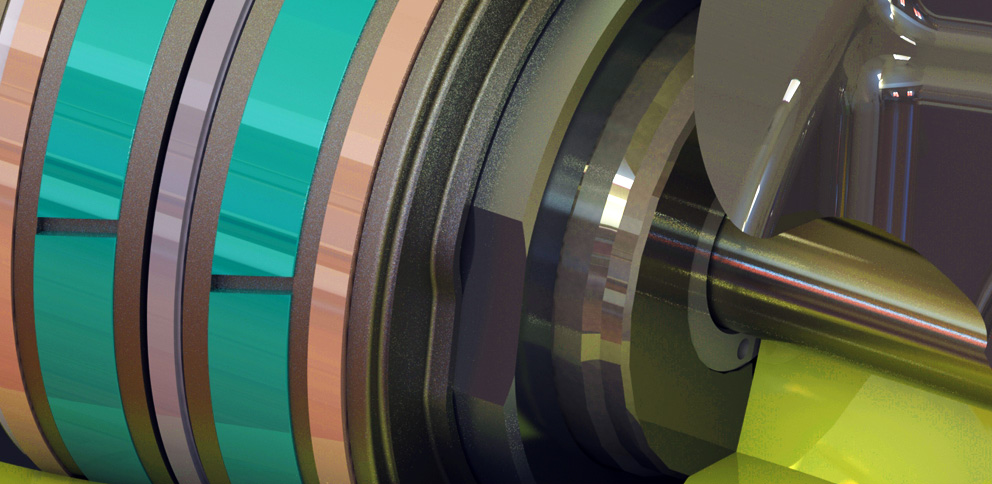

The patented LiRe process has proven itself in thousands of applications. It stands for the innovative method of connecting the piston with the rod in our hydraulic cylinders.

The two components are screwed together with the left-right-hand threading in the LiRe system. The right-hand thread piston is screwed on the piston rod with low torque. The nut, which prevents the piston from loosening, on the other hand is left-hand threaded. This special method of bonding is unique to Pacoma’s cylinders.

Consequently the piston and rod are safely and securely bonded. This lowers material costs, allows up to 5 times higher forces on the piston due to the larger thread diameter and significantly increases durability. At the same time, this bonding is easy to disengage as required. The complete cylinder can be disassembled on the field without any special tools, which makes maintenance much simpler and quicker and furthermore saves costs.

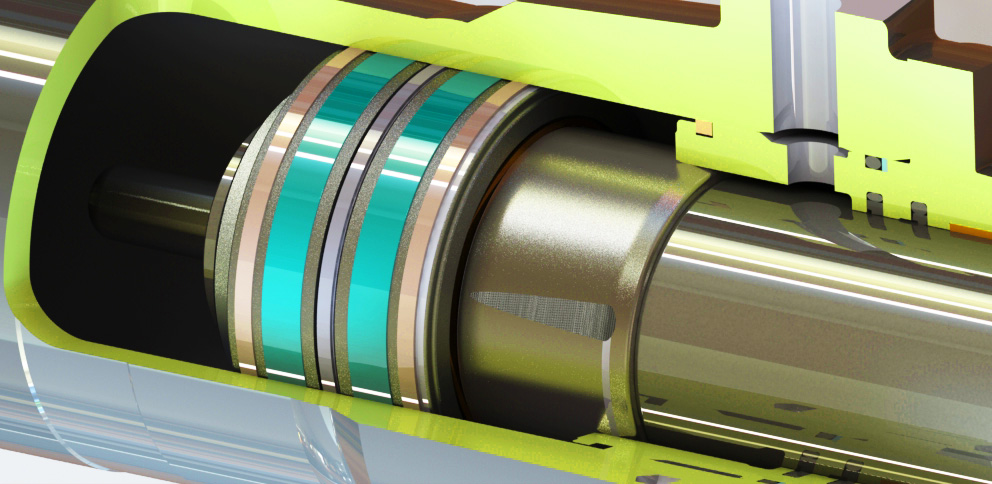

CuSt is our abbreviation for the special cushioning system used in our hydraulic cylinders. It refers to our innovative system for cushioning the impact at the end of a piston's movement. A cushioning system of this sort is strongly recommended particularly when a cylinder is operating at high speed or is carrying high loads.

The cushioning elements have a floating suspension in both an axial and radial orientation. Their operation is based on the principle of having a defined level of pressure in the opposing direction of the piston movement that reliably cushions and gently brakes the movement in the end phase of the stroke. The end pressure remains in the cylinder and does not affect the surrounding machine. This protects the machine, enhances operational safety and increases operating comfort. The life expectancy of the vehicles is extended and operators can do their jobs more comfortably.

Pacoma has extensive experience in calculating the required cushioning attributes in advance and then incorporating them into the hydraulic cylinders to exactly correspond to the requirements of that particular machine. In addition, all cylinders undergo internal checks and practical tests in the assessment area. Finally any cushioning system has to prove itself in practice. Subsequently on the basis of customer feedback, Pacoma will optimize the cushioning attributes.

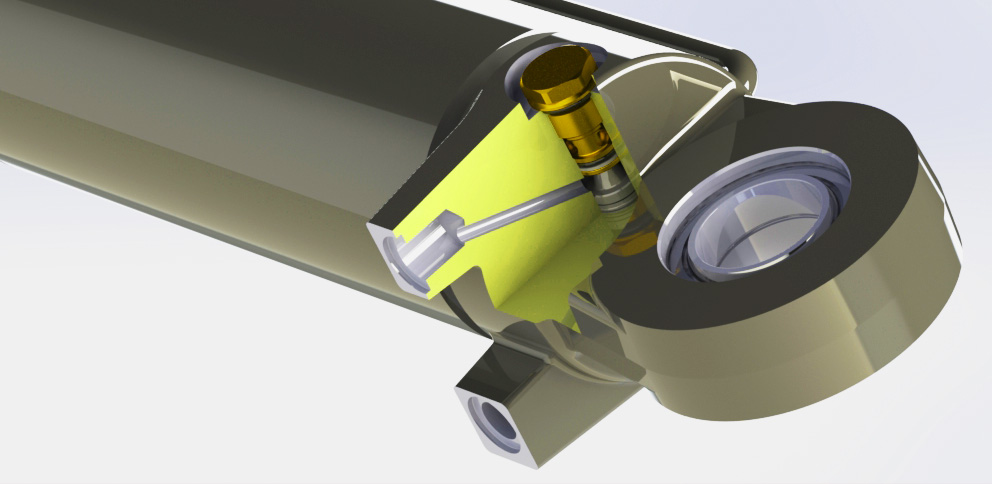

PaStab (Pacoma Stablilizer) refers to our special valve technology for hydraulic cylinders. This technology was orginially developed for large mobile devices, machines and vehicles ensuring a secure position even on uneven terrain and surfaces, thereby increasing operational safety.

The integrated valves in the cylinder can also be locked under high pressure conditions with no problem. This makes it possible to flexibly adjust the base of the machine to every terrain. Pacoma installs seat valves in PaStab cylinders which are unlocked hydraulically so that even in the event of a line breakage no pressure will be lost. Axle lock cylinders, support cylinders and bulldozer blade cylinders distinctly benefit operators of large cranes, excavators and bulldozers.

P3S is a position sensor system that makes it possible to automate and precisely replicate recurring work processes. A sensor monitors the position of the piston rod. A control unit processes these data and transmits the resultsvia the valve technology to the cylinder.

In this way the cylinder reaches exactly the desired position – regardless of a particular height, reach, angle or other movement process. This makes it possible to predefine a secure action radius so as to work safely in restricted areas.

Indeed, the application possibilities for this technology verge on the unlimited. Therefore we are continuously developing our P3S system to further extend its application.

At Pacoma, we define production as the whole chain of steps from purchasing to research to development and finally to actual manufacturing. Throughout the entire process our focus is constantly on quality and efficiency.

For cost-effective purchasing, we compare offers based on international market prices, order directly from producers whenever feasible and take advantage of currency exchange benefits. At the same time, we always operate as a reliable and fair partner with our international suppliers.

Our research and development department design and create hydraulic cylinders that fulfill all the specific requirements of our customers. Our customized cylinders are kept simple unless complexity is a prerequisite to optimize performance.

Our linked production facilities make use of modern manufacturing machinery enhanced by special handling robots. They are equipped for large scale production with consistently high quality. Our main factory at the Eschwege plant can readily produce 1000 hydraulic cylinders per day.

At Pacoma quality assurance work starts in purchasing. That is why we certify our suppliers. Our quality control begins in the incoming goods department where quality is constantly monitored. A 3D measuring machine ensures adherence to all critical parameters of incoming components.

Our consistently high quality products are the result of innovative engineering, modern manufacturing as well as systematic measurements and testing as evidenced by the following certification:

DIN EN ISO 9001: 2015 (Quality Management)

DIN EN ISO 14001: 2015 (Environmental Management)

DIN EN ISO 50001: 2018 (Energy Mangement)

DIN EN ISO 3834 - 2 (Quality for welding)

We do not rest on our laurels. Our engineering and production experts consult constantly and closely with our customers to ensure on-going developments and improvments of our hydraulic cylinders to keep abreast of ever-changing and increasing demands.

Pacoma maintains good relationships with international manufacturers in Europe, Asia and the USA. Working in collaboration we always strive for the best price-quality ratios. To this end, our colleagues in engineering and quality management inspect, test and certify suppliers' production facilities on site.

Pacoma makes use of Electronic Data Interchange (EDI) interfaces for processing supplier orders. With this paperless system all data is fed directly into our systems. This ensures a high level of accuracy and enables a real-time overview for inventory management, demand planning and order management.

Our purchasing spectrum encompasses the following main areas:

Rods and tubes (steel)

Seals and guides

Turned and milled components (steel)

Valves (Stop-, Pressure-, Load-holding-, Flow-control valves)

To apply to become a Pacoma supplier, please send us information regarding your company and product range as well as complete the PDF form for Supplier Information.

Downloads

Supplier self-assessment

Terms and conditions of supply

Terms and conditions of purchase

At Pacoma the engineering of all products is centrally managed at our headquarters in Germany. For products based on common designs, production occurs both in Germany and in China. Our sales and distribution network are managed in Germany, China and the USA.

EUROPE/Deutschland

Pacoma GmbH

Königsberger Str. 12

D-37269 Eschwege

Contact

Phone: +49 (0) 5651 - 924 - 0

Fax: +49 (0) 5651 - 924 - 679

Email: pacoma.info(at)leggett.com

CHINA/Fenghua

Pacoma China Hydraulic Equipment Co., Ltd

No. 18 Xiaowangmiao Section Jiang Ba Line

Fenghua, Zhejiang Zip Code 315500

Contact

Phone: +86 (574) 888 90 999

Fax: +86 (574) 889 50 602

Email: pacoma.info.cn(at)leggett.com

USA/North Carolina

Pacoma USA Inc.

145 Southpark Drive,

Wallace, NC 28466

USA

Contact

Phone: +1 650 241 1433

Email: pacoma.USSales(at)leggett.com

Pacoma has taken a leading role in the industry in environmental protection measures. Our certification under the international environmental management standard DIN EN ISO 14001 attests to Pacoma's environmentally correct planning, execution, control and optimization of all relevant processes.

On this basis, Pacoma systematically saves energy and resources, reduces emissions and distances travelled, prevents waste generation and contamination to the largest extent possible and establishes a structure for the most extensive recycling.

Pacoma is one of the world's leading suppliers of hydraulic cylinders. Our headquarters in Eschwege, Germany employs presently 230 employees and trainees.

We have a wide range of positions, extensive training possibilities and excellent career development opportunities. Positions are available in research and development, production, quality management as well as administration, sales and management.

Pacoma is always interested in getting to know capable and motivated employees. Please apply for one of our available positions, a trainee position or send us a general application indicating your interests.

pacoma.karriere(at)leggett.com

APPRENTICESHIPS & PRACTICAL PHASES:

WAREHOUSE LOGISTICS SPECIALIST M/F/D

WORKING STUDENT RESEARCH & DEVELOPMENT: SENSOR TEAM M/F/D

WORKING STUDENT SALES & OPERATIONS PLANNING (S&OP) M/F/D

EXPERIENCED PROFESSIONALS & EXPERTS:

MACHINE AND PLANT OPERATOR M/F/D

EMPLOYEE M/F/D FINAL INSPECTION

EMPLOYEE M/F/D FOR INTERNAL TRANSPORTATION / INTRALOGISTICS

EXECUTIVES & MANAGEMENT: